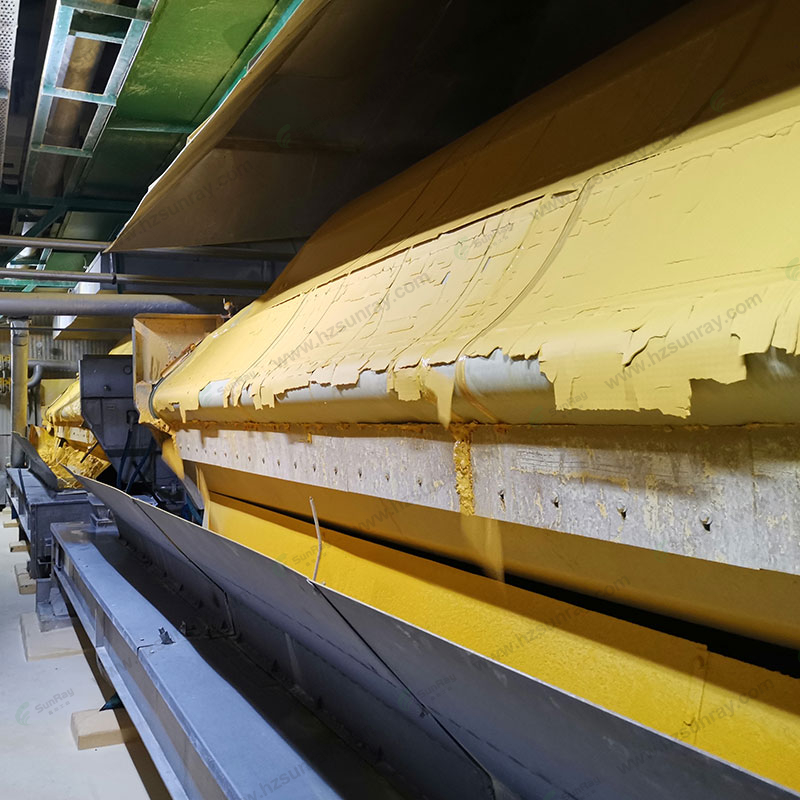

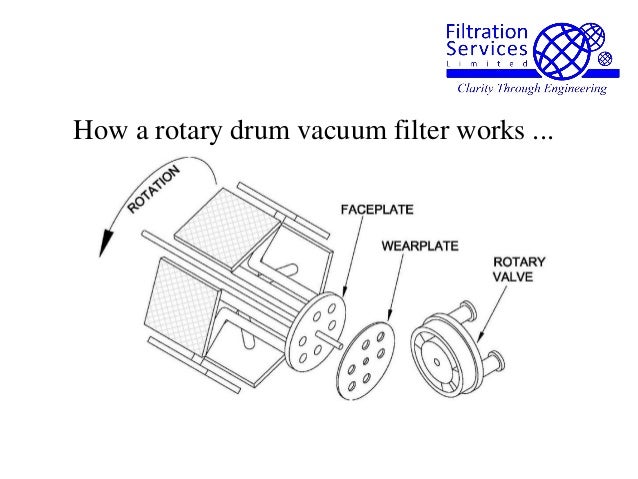

Scraper Discharge: is the most common drum filter discharge. After dewatering, the cake is removed from the filter cloth by a scraper blade just prior to the re-submergence of the drum. The scraper serves mainly as a deflector to direct the cake, dislodged by an air blowback, into the discharge chute.Normally a discharge device will be selected based on the process material characteristics and how readily it is released from the filtering media. The rotary vacuum filters can discharge its filtered cake by means of any one of several discharge arrangements. Note: can be of some usefulness (not specific on rotary drum filters).Įdited by kkala, 30 October 2012 - 03:45 PM.Rotary Vacuum Drum Filters provide a wide range of liquid-solids separation for many types of industrial processing flow sheets. They offer the operating flexibility to handle dewatering, washing and clarification applications, or a combination of the two. The thread may be continuation of, but "assignment" is understood to mean work much longer than an exercise. Some filter suppliers may be willing for help or supply brochures, e.g. The latter (even in pilot plant) could be more useful, yet such data may be hard to find. So empirical equation for cake resistance had better be derived experimentally, as books indicate if not included in the scope of student work, something has to be adopted through instructor's help or apply ready specific data from practice, based on operation of an actual Mg(OH)2 drum filter. I have seen disk (not rotary) vacuum filters (separating gypsum from phosphoric acid) to produce mud instead of cake, for "the resistance is sensitive to the method used in preparing the slurry and to the age and temperature of the material". Specific cake residence is theoretically dependent on particle size and porosity, yet in practice other factors also intervene (slurry does not contain only rigid particles, but also agglomerates affecting resistance to flow) see above, especially "compressible or incompressible filter cakes" at the end of Principles of Cake Filtration. An example of rotary drum filter for CaCO3 is included. The rotary vacuum drum filter was patented in 1872 and, since then, has been used extensively in the processing of chemicals, pharmaceuticals, cosmetics, and minerals.Compositechs rotary drum filter design provides reliable liquid/solid separation with minimum operator attention and maintenance requirements even in heavy duty, 24-hour continuous operation.

"Unit Operations in Chemical Engineering" (McGrawHill, 1993) by McCabe, Smith, Harriot Chapter "Mechanical Separations", paras on Filtration, Cake Filters, Principles of Cake Filtration (excluding centrifugal filtration). Information on filtration can be seen in any relevant book, e.g. Thanks, breizh, for the interesting process description of (caustic or deadburned) magnesia from limestone and sea water.

0 kommentar(er)

0 kommentar(er)